Florida’s extreme weather conditions destroy millions of dollars worth of business signage every year. From hurricane-force winds exceeding 155 mph to intense UV radiation that breaks down materials faster than anywhere else in the country, the Sunshine State presents unique challenges that standard signage simply cannot survive.

Jacksonville businesses face additional weather complexities beyond typical Florida concerns. Coastal salt air accelerates corrosion, while the city’s position along major storm tracks means frequent exposure to severe weather systems. Many business owners discover these harsh realities only after expensive signs fade, crack, or blow away entirely.

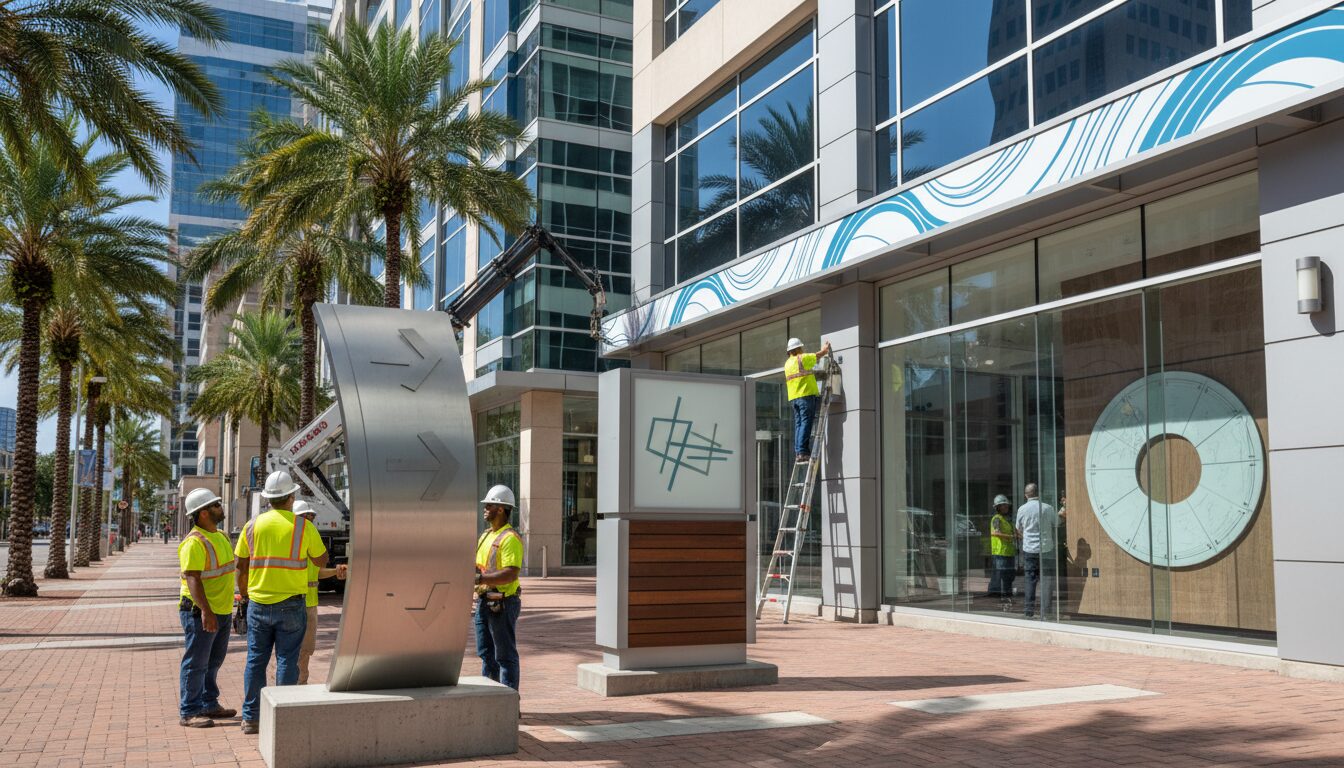

Florida-proof signs represent a specialized approach to commercial signage designed specifically for these extreme conditions. This comprehensive guide explains the engineering principles, materials science, and construction standards that separate weather-resistant signage from standard products. With insights from SignLab JAX’s experience protecting Jacksonville businesses through multiple hurricane seasons, you’ll understand how to invest in signage that survives Florida’s toughest challenges.

Understanding Florida’s Unique Weather Challenges

Florida experiences some of the most extreme weather conditions in North America, creating a perfect storm of factors that systematically destroy standard signage materials. From 1980-2024, there were 94 confirmed weather/climate disaster events with losses exceeding $1 billion each to affect Florida. These events included 7 drought events, 4 flooding events, 5 freeze events, 33 severe storm events, 36 tropical cyclone events, 4 wildfire events, and 5 winter storm events.

Hurricane Wind Forces: The strongest hurricanes can have winds in excess of 155 mph. Hurricane force winds can easily damage or destroy mobile homes and other non-permanent structures, often moving them well away from their foundations. Because of Florida’s flat terrain, strong winds do not rapidly weaken after the storm makes landfall. Standard signage mounting systems and materials cannot withstand these extreme forces without specialized engineering.

UV Radiation Intensity: Virtually the whole spectrum is of concern, which is why long term exposure to solar radiation should be limited. Florida’s year-round intense sunlight accelerates photodegradation in sign materials. Red, Yellow, and Orange: These colors fade the fastest because their pigments absorb more UV radiation. Blue and Green: More resistant to fading but still require UV protection.

Salt Air Corrosion: Jacksonville’s coastal location exposes signage to salt-laden air that accelerates metal corrosion and degrades protective coatings faster than inland environments. This combination of factors requires materials and construction methods specifically engineered for extreme conditions.

Hurricane-Resistant Construction Standards

Florida-proof signs must meet rigorous engineering standards developed after Hurricane Andrew’s devastating impact in 1992. In 1992 hurricane Andrew hit Florida and caused an estimated $25 billion dollars in damages. This became a wake up call for the construction industry. Wind zone levels were not adequate, the existing standards were not being adhered to, and codes were not being enforced.

Testing Requirements: Modern hurricane-resistant signage undergoes comprehensive testing protocols. The most common test for the hurricane market is the impact and cycling test, designed to simulate windborne debris striking a window or element of the building during a hurricane. These tests evaluate both impact resistance and sustained wind pressure capabilities.

Design Pressure Standards: Signs must withstand specific design pressures based on location and height. Test requirements call for entire systems – glass, frames, sealants, locks and fasteners to resist wind-borne debris followed by severe pressure cycling. Jacksonville’s position requires signs capable of withstanding design winds up to 130 mph in most commercial areas.

Mounting System Engineering: Professional installation involves engineered mounting systems that transfer wind loads safely to building structures. Inadequate mounting represents the primary failure point during severe weather, regardless of sign material quality. Proper engineering analysis considers both positive and negative pressure loads that can literally pull signs from buildings.

Advanced Materials Science for Florida Conditions

Florida-proof signs utilize materials specifically engineered to resist the state’s extreme environmental conditions. Standard signage materials that perform well in moderate climates fail rapidly under Florida’s harsh conditions, making material selection critical for long-term performance.

UV-Resistant Polymers: UV degradation, affects many natural and synthetic polymers including some rubbers, neoprene and polyvinyl chloride (PVC). With too much exposure, these materials can: [become brittle, crack, or discolor]. Advanced polymer formulations include UV stabilizers that maintain material integrity under constant sun exposure.

Corrosion-Resistant Metals: Aluminum alloys and stainless steel grades specifically chosen for marine environments resist salt air corrosion that destroys standard metals within months. Protective coatings undergo accelerated weathering tests simulating years of Florida exposure before application approval.

Impact-Resistant Glazing: Large missile impact tests simulating large wind-borne debris, such as tree limbs, sign posts and other large objects, are required for products such as entrances and storefronts installed up to 30 feet above grade. Florida-proof signs incorporate similar impact-resistant materials designed to withstand flying debris without catastrophic failure.

Color-Fast Pigments: Advanced pigment systems maintain color integrity under extreme UV exposure. Traditional inks and paints fade within months in Florida’s intense sunlight, while weather-resistant formulations maintain appearance for years under the same conditions.

Energy Efficiency and Smart Technology Integration

Modern Florida-proof signs incorporate energy-efficient technologies that reduce operating costs while maintaining performance under extreme conditions. LED lighting systems specifically designed for harsh environments provide consistent illumination while withstanding humidity, temperature fluctuations, and electrical stress from lightning strikes.

LED Weather Resistance: Professional-grade LED systems include sealed housings, surge protection, and thermal management designed for Florida’s challenging electrical environment. Standard LED products fail rapidly due to moisture infiltration and electrical stress from frequent thunderstorms.

Smart Controls and Monitoring: Advanced sign systems include remote monitoring capabilities that alert owners to maintenance needs before failures occur. Temperature sensors, moisture detection, and performance monitoring provide early warning of developing problems that could lead to complete system failure during storms.

Energy Management: Efficient power systems reduce electrical stress and heat generation that accelerate component failure in Florida’s climate. Proper electrical design includes surge protection specifically rated for lightning-prone areas and backup power systems for critical signage applications.

Automated Maintenance Alerts: Smart technology integration enables predictive maintenance scheduling based on actual environmental exposure rather than arbitrary time intervals, optimizing performance while minimizing unexpected failures.

Professional Installation and Maintenance Requirements

Florida-proof signs require professional installation and maintenance programs specifically designed for extreme weather conditions. Proper installation techniques and ongoing maintenance represent the difference between signage that survives multiple hurricane seasons and expensive failures during the first major storm.

Structural Engineering Analysis: Professional installation begins with structural analysis of mounting surfaces and load calculations specific to local wind conditions. Building attachment points must transfer extreme loads safely without compromising building integrity or sign performance.

Preventive Maintenance Programs: All signs shall be maintained in good repair at all times by their owners, lessors or other users. Examples of required sign maintenance include: Keeping exposed sign surfaces clean so that the sign’s message does not become obscured, keeping painted sign portions painted to prevent chipping, peeling or flaking of paint, replacement of missing, torn or defective parts or portions of such sign.

Storm Preparation Protocols: Professional maintenance includes pre-storm inspection and preparation procedures that maximize survival chances during severe weather. This involves securing loose components, checking drainage systems, and verifying electrical connections before storm season.

Post-Storm Assessment: Experienced technicians can identify storm damage that appears minor but indicates potential failure points requiring immediate attention. Early intervention prevents small problems from becoming complete system failures during subsequent weather events.

Conclusion

Florida-proof signs represent essential infrastructure investments for Jacksonville businesses operating in one of the country’s most challenging weather environments. The combination of hurricane-force winds, intense UV radiation, salt air corrosion, and frequent severe thunderstorms demands specialized engineering and materials unavailable in standard signage products.

Professional specification and installation of weather-resistant signage protects marketing investments while ensuring business visibility during and after severe weather events. The initial investment in Florida-proof construction typically pays for itself by avoiding repeated replacement costs and maintaining business operations when competitors face signage failures.

Understanding the engineering principles behind weather-resistant signage enables informed decision-making that protects both immediate functionality and long-term return on investment. In Florida’s extreme environment, cutting corners on signage construction consistently leads to expensive failures and lost business opportunities.

Ready to protect your Jacksonville business with Florida-proof signage engineered for extreme conditions? Contact SignLab JAX for comprehensive consultation on weather-resistant signage solutions designed specifically for Northeast Florida’s challenging environment.